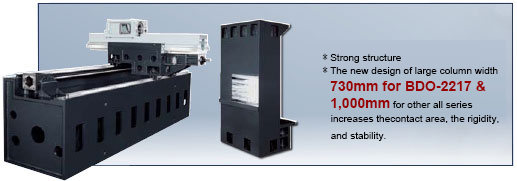

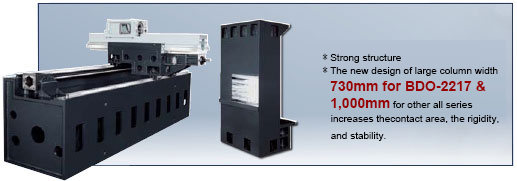

High-Rigidity, High-Precision & High-Efficiency Design Concept

|

| Double Column Vertical Machining Center | |

|

|

|

|

Perfect Structure Design High Quality Guarantee

|

|

|

| Different Types Of Spindles Are Available | |

|

The gear-driven spindle provides spindle speed of 4,000rpm and 6,000rpm with high output torque which is the best choice for frequent heavy-cutting operations. |

|

ZF spindle has higher torgue than belt-driven spindle. ZF spindle provides higher rotational speed than gear driven does. ZF gear box has 1:4 speed reduction ratio mechanism. It enlarges output torque by 4 times. It offers an extra choice for users who needs high rotation speed and high torque for machining operation. |

|

The design of the back holder of cross-beams neatly aligns hydraulic unit, cooling machines, and spare parts, etc., and meets the requirement of CE regulations. This design offers two advantages: |

| ITEM / MODEL | BDO-2217 | BDO-2223 | BDO-3217 |

| TRAVEL | |||

| X AXIS (WORK TABLE) | 2,200mm(86.6″) | 2,200mm(86.6″) | 3,200mm(125.9″) |

| 2 LINEAR GUIDE WAYS 3*2 SLIDING BLOCKS |

2 LINEAR GUIDE WAYS 3*2 SLIDING BLOCKS |

2 LINEAR GUIDE WAYS 4*2 SLIDING BLOCKS |

|

| Y AXIS (SADDLE) | 1,600mm(63″) | 2,100mm(82.7″) | 1,600mm(63″) |

| 2 LINEAR GUIDE WAYS 2*2 SLIDING BLOCK |

2 LINEAR GUIDE WAYS 2*2 SLIDING BLOCK |

2 LINEAR GUIDE WAYS 2*2 SLIDING BLOCKS |

|

| Z AXIS (HEAD) | 1,000mm(39.4″)/ (opt800mm(31.5″)) |

1,000mm(39.4″)/ (opt800mm(31.5″)) |

1,000mm(39.4″)/ (opt800mm(31.5″)) |

| 2 BOX GUIDE WAYS | 2 BOX GUIDE WAYS | 2 BOX GUIDE WAYS | |

| DISTANCE FROM SPINDLE NOSE TO TABLE SURFACE | 200-1,200mm(7.8″-47.2″)/ (opt200-1,000mm(7.8″-39.4″)) |

200-1,200mm(7.8″-47.2″)/ (opt200-1,000mm(7.8″-39.4″)) |

200-1,200mm(7.8″-47.2″)/ (opt200-1,000mm(7.8″-39.4″)) |

| DISTANCE BETWEEN COLUMN | 1760mm(69.3″) | 2360mm(92.9″) | 1760mm(69.3″) |

| WORK TABLE | |||

| TABLE SIZE | 2000mm*1500mm (78.7″*59.1″) |

2000mm*2000mm (78.7″*78.7″) |

3000*1500mm (118.1″*59.1″) |

| T-SLOT SIZE | 7x22mmx200mm | 9x22mmx200mm | 7x22mmx200mm |

| DISTANCE FROM TABLE SURFACE TO GROUND | 830mm(32.7″) | 885mm(34.8″) | 830mm(32.7″) |

| MAX. TABLE LOAD | 6,000kgs(13,200lbs) | 8,000kgs(17,600lbs) | 8,000kgs(17,600lbs) |

| SPINDLE | |||

| SPINDLE TAPER (BT/CAT) | BT50/CAT50 | BT50/CAT50 | BT50/CAT50 |

| SPINDLE SPEED RPM(BT50) | 6,000rpm(P & G)(opt.8,000/10,000rpm) | ||

| FEED RATE | |||

| RAPID TRAVERSE(X/Y/Z) | 20/20/10M/Min. (787/787/393IPM) |

20/20/10M/Min. (787/787/393IPM) |

20/20/10M/Min. (787/787/393IPM) |

| CUTTING FEEDRATE(X/Y/Z) | 1~8000mm/min | 1~8000mm/min | 1~8000mm/min |

| MOTOR | |||

| SPINDLE BT50 (CONT. /30 MIN.) | 22/26kw(30/35HP) | 22/26kw(30/35HP) | 22/26kw(30/35HP) |

| AC SERVER MOTOR(X/Y/Z) | X,Y,Z:7KW-30NM | X,Y,Z:7KW-30NM | X,Y,Z:7KW-30NM |

| COOLANT PUMP | 1250W | 1250W | 1250W |

| LUBRICATION PUMP | 60W | 60W | 60W |

| OIL CIRCULATING COOLANT SYSTEM FOR SPINDLE | 1220W | 1220W | 1220W |

| ATC | |||

| MAGAZINE CAPACITY FOR ARM TYPE | 32 TOOL/(OPT.40/60 TOOL) | ||

| MAX. TOOL DIAMETER(WITH ADJACENT POCKET EMPTY) | BT50-Ø125MM | ||

| MAX. TOOL LENGTH | 300mm(11.74″) | ||

| MAX. TOOL WEIGHT | 20Kg(44lbs) | ||

| Tool Change Time(T TO T/C TO C) | 8/12 SEC. | ||

| ACCURACY | |||

| POSITIONING ACCURACY | ±0.01 mm | ±0.01 mm | ±0.01 mm |

| REPEATABILITY ACCURACY | ±0.003 mm | ±0.003 mm | ±0.003 mm |

| MISC. | |||

| AIR PRESSURE | 6 Kg / cm² | 6 Kg / cm² | 6 Kg / cm² |

| POWER SUPPLY | 50KVA, 220V, 3 PHASE, 50/60HZ | ||

| MACHINE WEIGHT | 26,000kgs(57,200lbs) | 28,000kgs(61,600lbs) | 28,000kgs(61,600lbs) |

| MACHINE DIMENSION (L×W×H) | 67600*5100*3900mm | 67600*6960*3900mm | 8530*5100*3900mm |

| CONTROLLER | OiMD/31iMB | ||